FS4 – Frozen Squirrels tell no tales. Keeping our payload cozy.

No one likes a rock-solid frozen squirrel, especially the squirrel.

In order to keep our pilot warm we have to find a method to stay warm but not weigh the payload down too much for our lightweight mission goals.

It is cold up there.

FS3 climbed to 9,100m (just under 30,000 ft) before the signal was lost. As FS3 climbed at a steady rate, the internal temperature of the payload was declining as the outside air temps reached -30C (-22 F). The final report inside the payload was a temperature of -12.8C (9F).

Had the mission not prematurely ended due to the failed antenna wire supporting, it is clear the temperatures would continue to fall below the point where the battery and other components would freeze up and fail. Most of the electronic parts are rated to -20C. FS3 would have reached that point within another hour of flight. A solution to keep our FS4 squirrel warm is needed.

How to keep our squirrel warm? The team postulated several possible solutions, and these were investigated.

Rust to the rescue?

One source of heat energy can come from exothermic chemical reactions, such as found in every day pocket hand warmers. These warmers function through an everyday common chemical reaction of iron to iron oxide (A.K.A. Rust). I hacked some warmers to make a smaller size by placing the material (Iron powder and some insert powders) into tea bags. The warmer works by exposure to air. The reaction begins when water vapor, in the air, starts to rust the iron powder. I measured the heat produced by placing the warmer in an insulated container with a DS18B20 temperature probe. While the warmer produced significant heat quickly, it could only sustain the heat for an hour or so. This solution had a number of drawbacks. 1. Iron is heavy. 2. Heat is produced at the start of the mission when you first expose the material to air. Heat is really needed after the first hour of flight, so the timing of when the heat is produced is wrong and not long lived enough for our flights. 3. Additionally the iron powder is very fine and leaks out of the tea bags. Iron powder in an electronic environment is not going to work well. The leakage problem could be solved, but the idea was not going to work. Idea abandoned.

Does this insulation make me look fat?

FS3 used 1 inch thick Styrofoam insulation and could only ward off the outside cold for an hour or two. Thicker/better insulation can be added to the payload enclosure. However, this adds weight to the balloon and will require more lift. This remains an open idea and more work remains. It is likely that this will be at least part of the solution.

How about an electric blanket?

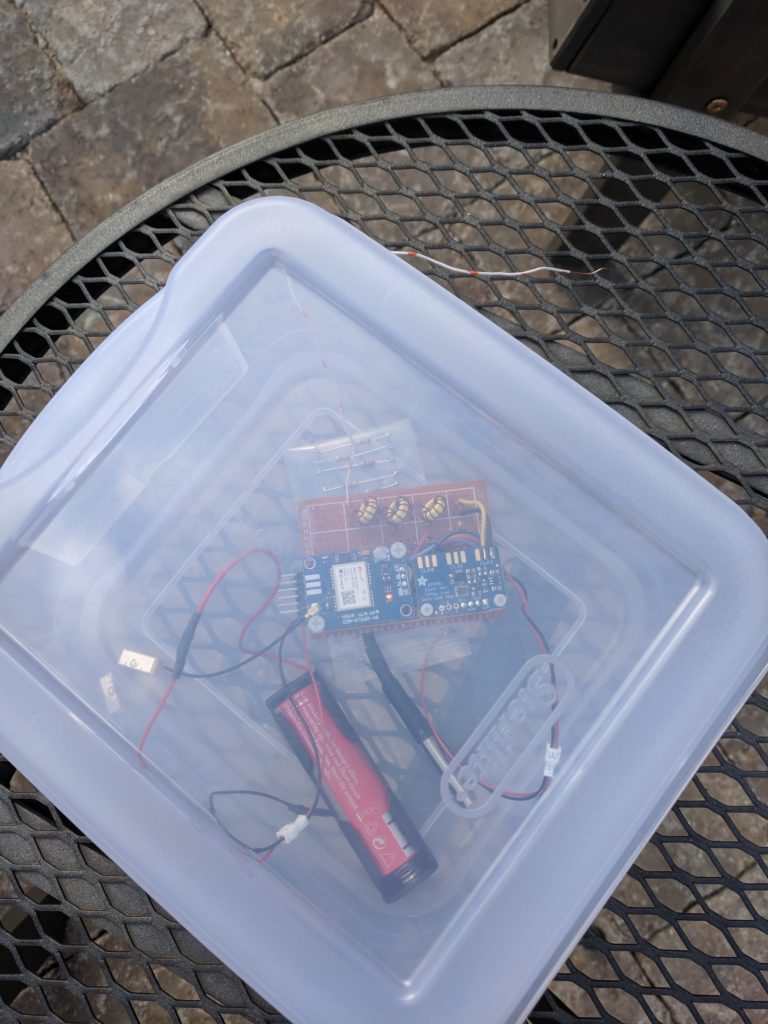

Heat can be generated from the battery by running it through a resistive load (A resistor). This will certainly work, but there is a cost of needing enough battery to run the heater. More battery equals more weight which means a balloon with more lift.

Use what ya got, make more heat with the electronics on board?

Instead of switching devices off when not needed, to save power, leave them running to produce more heat. Like the electric blanket idea, this will require more battery.

Look into the sun!

During the day solar heat can be captured to produce heat inside the payload cabin. In effect a greenhouse. A number of the WarPig balloon flights by KA9CQL & N9RZR used a simple plastic soda bottle as the payload cabin. Despite, what seems like a lack of insulation, their balloons kept warm. Most of their flight hours were during the daytime and the inside temps were above room temperatures even at high altitude with sub zero temps outside. Their electronics packages burned a lot more energy than FS3 did, so they were making more internal heat to begin with, but the bottle appears to be collecting solar energy and storing it inside due to the green house effect.

Time to put away your calculators, the test has begun.

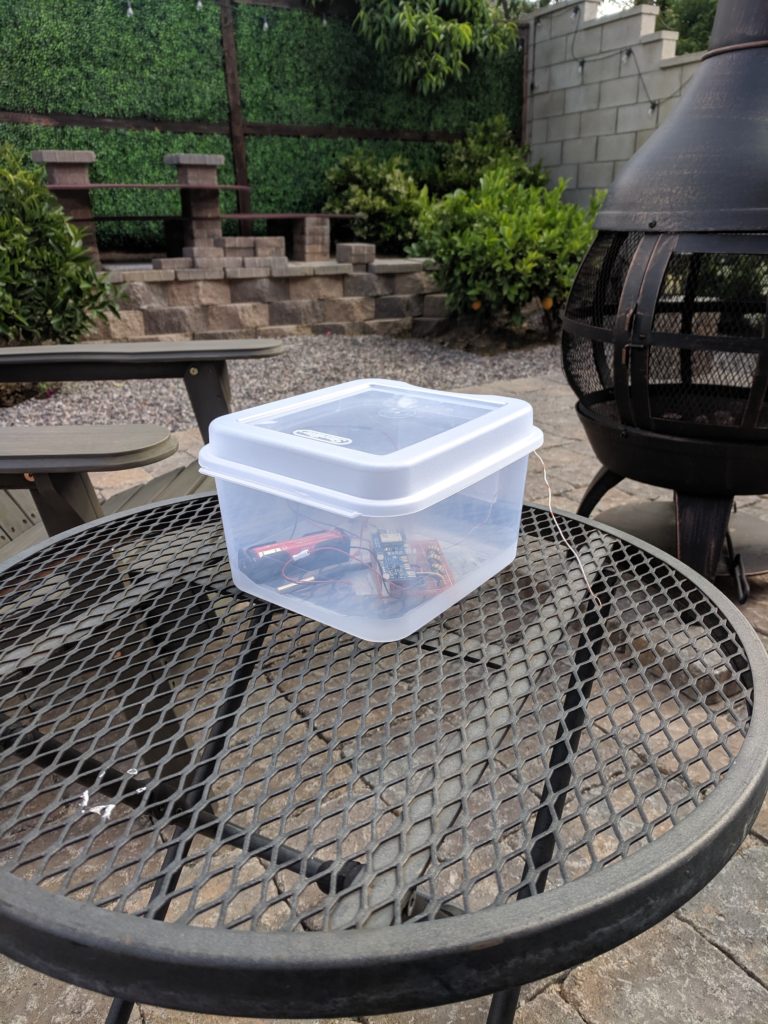

The FS4 hardware was built with an electric blanket to help warm the payload cabin.

A larger 18650 3000mah capacity battery was used in the design to power the extra heat generation. To protect it from passing animals, dirt and rain, the FS4 electronics payload was put into a temporary milky white plastic box and left outside during the day to run. The test goal was to run the heater at full blast and see how long the battery could operate the payload.

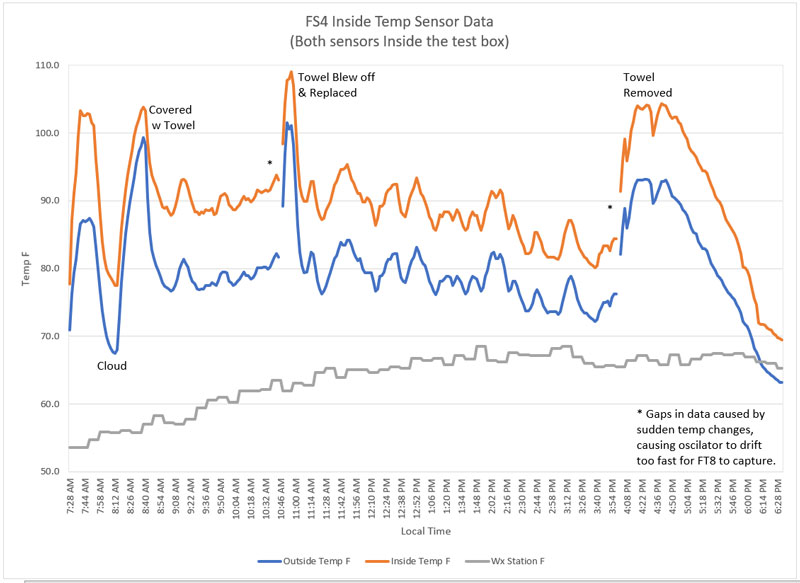

In mere minutes the inside temps got uncomfortably hot inside the box. Our Squirrel was not going be a frozen berg, but rather cooked alive! However, a passing cloud came to the rescue of our test squirrel and the inside temps dove back to a comfy level very quickly. This change in heat could not be accounted for from the heater (Which was on the whole time).

To keep FS4 from cooking on the ground, I threw a towel over the plastic box and temperatures went back down. Later in the day, a gust of wind blew the towel off the box and temperatures went up quickly and then back down as the towel was replaced. The increase of temperature was clearly solar generated heat.

It appears the squirrel can be kept warm during the daylight hours by harvesting heat from the sun’s rays. At high altitude, there is less air to absorb solar radiation, so the greenhouse effect should be even greater. This is good news because, we won’t have to use battery to keep the payload warm during the day, so that energy can be saved for heating during the night hours.

Pencils down, test over.

FS4 passed the test and a lot was learned.

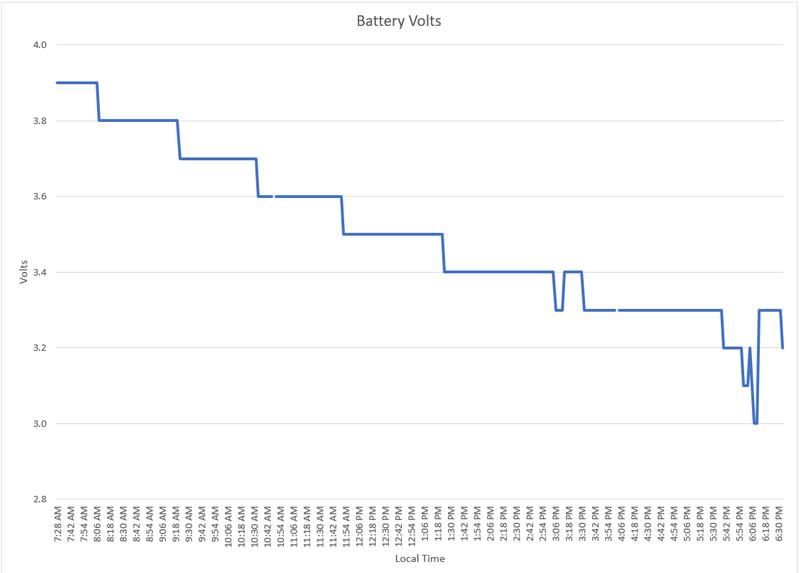

The electronics with full heat ran 11 hours on a 18650 battery. This will be sufficient to heat a payload overnight. More testing will confirm this.

It is odd that the voltage went back up at the end of the test. More investigation is needed to explain this. The battery, measured with an accurate bench meter, after the test did read 3.4 volts. Yet the battery lacked the ability to run the electronics. (Usually 2.9 volts is enough to power up) It seems there was voltage but no ability to provide sufficient current. More investigation is needed to explain this.

The test was started indoors, where the beginning temp was around 70F. The box was quickly taken outside into full sun on a partly cloudy day. The response to temperature was immediate.

Once in the sun, the FS4 electronics, inside the temporary plastic box, got hot fast, and to prevent it from overheating, I threw the towel over it to keep it cool. You can see how fast the temp changed when the towel was added and removed. When the temperature changed rapidly, the radio oscillator also drifted in frequency rapidly and this caused the FT8 decoder to fail on a few telemetry messages. Thus there are some short data gaps. Once the temp change slowed down the decoder continued to receive the telemetry. The payload cabin, will need insulation to prevent sudden rates of temperature change.

The “Inside Temp” sensor is consistently higher than the “Outside” sensor. For this test they were both in the same box, but the inside sensor is next to the heater switching transistor and radio board, so it is likely picking up some heat from these devices. This is good because we want to keep the radio warm and we need to measure the radio’s temperature for frequency calibration during transmit. The outdoor sensor was laying on the bottom of the box and may have been conducting heat into the table below.

The greenhouse effect is no surprise, but it was surprising to see how quickly the sun can heat the payload above 100F. Had the cloud not passed it would have gone much higher. The design of the payload cabin, will take advantage of this effect. FS4 still needs to keep the cold out at night, so insulation is still required and testing is necessary to see if the heater can ward off the frigid cold for 8 hours or more. The foam used in the past was bright white and would not absorb much heat. Will painting the foam black absorb enough heat and radiate that heat inside the cabin? Stay tuned.

73s de Don KJ6FO